Sector:

Ports & Shipyards

Expertise:

Heavy lifting

Marine transport

Benefits:

Rapid response

Reduced disruption

Location:

Malaysia

Jumbo-sized ships trigger innovation in the salvage industry.

On the night of July 29, 2011, a large bulk carrier collided with a general cargo vessel in the busy Straits of Malacca. The bulker sank to the bottom of the shallow straits, limiting traffic in one of the busiest shipping routes in the world.

As the ship was too big to accurately position cutting chains underneath it using traditional methods, Mammoet was called in to find an alternative solution. By engineering a new precision drilling method, Mammoet could position the cutting chains accurately.

This method allowed Mammoet to cut up the 230-meter-long hull into manageable pieces and remove them from the straits.

As modern ships are increasing in size and weight, they’re becoming more difficult to salvage, and traditional techniques of positioning cutting chains have limited accuracy that can lead to unacceptable deviations in section weight when cutting up big ships.

With a breadth of 32 meters and a deadweight of 70,424 tons, this bulk carrier was one of those large ships. Therefore Mammoet engineered a new directional drilling system to position the chains for the cutting of big vessels into precisely measured parts.

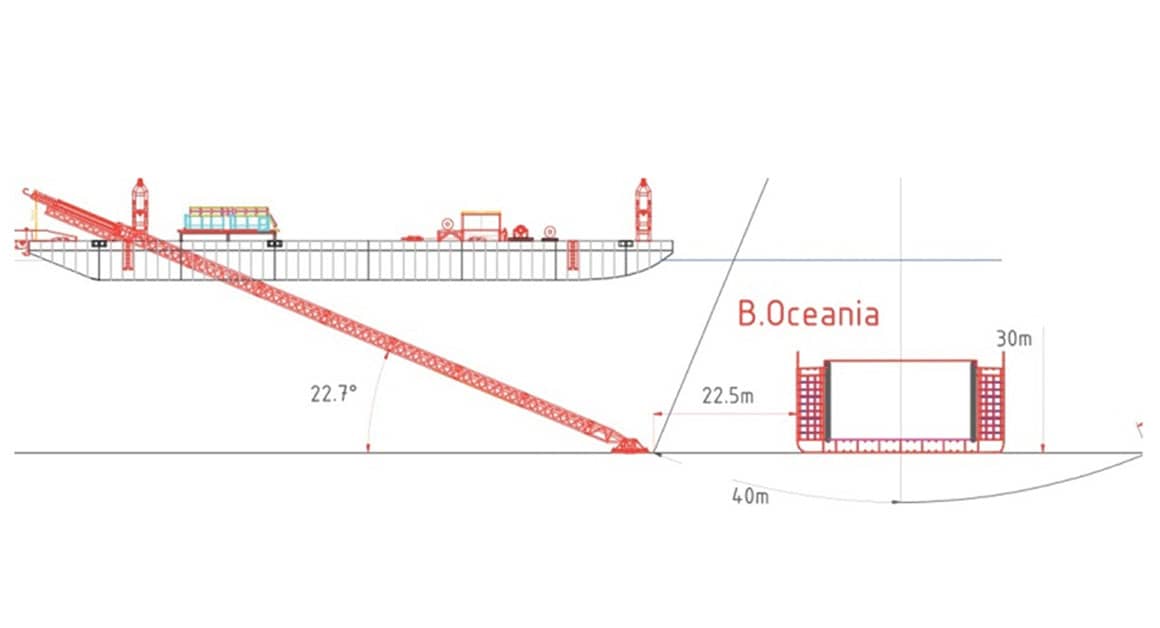

With the Submerged Directional Drilling System, Mammoet could pinpoint the exact positions to drill underneath the wreckage, from one side to the other. The modified horizontal directional drilling rig was placed on a tailor-made stinger beam and fitted alongside a barge. The stinger was then submerged at an angle of 22.7 degrees until its front reached its exact designated position on the ocean floor.

At this point, drilling could begin. Once the drill bit resurfaced on the other side of the ship, the cutting chains were run through the created pilot holes. With the chains in place, the crew could saw the crippled ship into precisely proportioned sections.

The chosen method was the only way to accurately run cutting chains under the 32-meter beam of this large bulker. Any other method would have been too imprecise to cut a ship this size into manageable pieces.

Adapting to maritime industry developments, Mammoet engineered a new way to safely and effectively raise large vessels - and in this particular case, free up the busy Straits of Malacca.