Sector:

Nuclear Power

Expertise:

Heavy lifting

Heavy transport

Benefits:

Increased safety

Protected infrastructure

Location:

France

Nuclear decommissioning through a bottleneck.

In the French Ardennes, the Chooz A nuclear plant was scheduled for decommissioning. Mammoet France was contracted to remove the plant’s heavy components, but the Chooz A offered a special challenge: it was located inside a mountain.

A unique design feature among nuclear plants, the mountain location required solutions that allowed work in a very limited space.

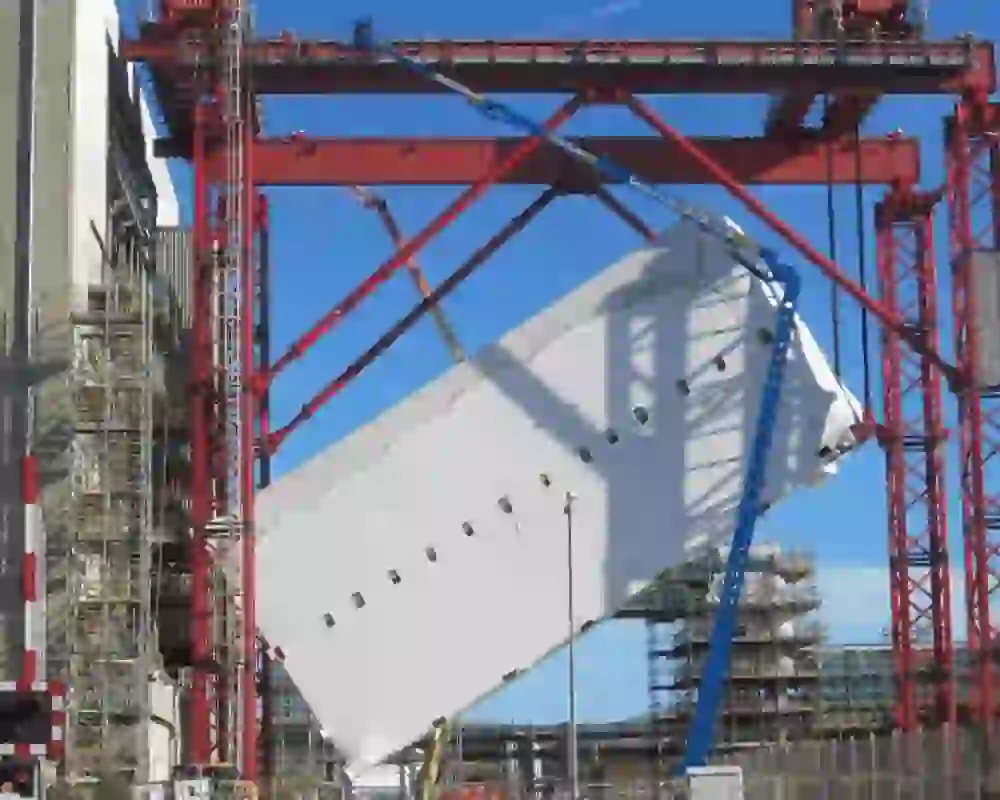

Mammoet responded by designing and building a range of tailor-made equipment for the job. The highlight of the project was the removal of four 120-ton steam generators through a narrow angled corridor. With a hydraulic rotating mechanism, Mammoet successfully removed the steam generators from their foundation positions – sometimes moving them through openings with less than 100 millimeters to spare.

With the Chooz A plant literally inside the mountain, there was no way to extract the 120-ton units in a straight line through the roof or walls, and stringent nuclear safety regulations ruled out most scenarios for the removal of the steam generators. With minimal exposure to contamination time in mind, Mammoet devised a solution that could safely and in the shortest possible interval get the units through the cornered corridor and out of the containment area.

Mammoet came up with an approach and designed the tools needed for the job. Leading the innovations was a rotating mechanism powered by four hydraulic jacks. This groundbreaking device was capable of tilting the steam generators progressively during lifting as they were moved forward with the overhead gantry crane.

Using trolleys adapted for the existing rail system, the steam generators were safely moved into a decontamination area and afterward removed by SPMTs.

Mammoet was able to swiftly extract the steam generators from a seemingly impossible position by conducting thorough research and applying its extensive engineering expertise.

Since successfully wrapping up the Chooz A project, Mammoet has been contracted to handle several future steam generator removals all over Europe. Innovations like the system created for the Chooz A reactor can undoubtedly be put to use in many of these projects. And should circumstances require a different solution, Mammoet will create the tools and strategies to do the job efficiently and safely.