Sector:

Offshore Wind

Offshore

Oil and Gas

Expertise:

Crane lifting

Load-in & load-out

Benefits:

Flexible operations

Optimized schedule

Record breaker

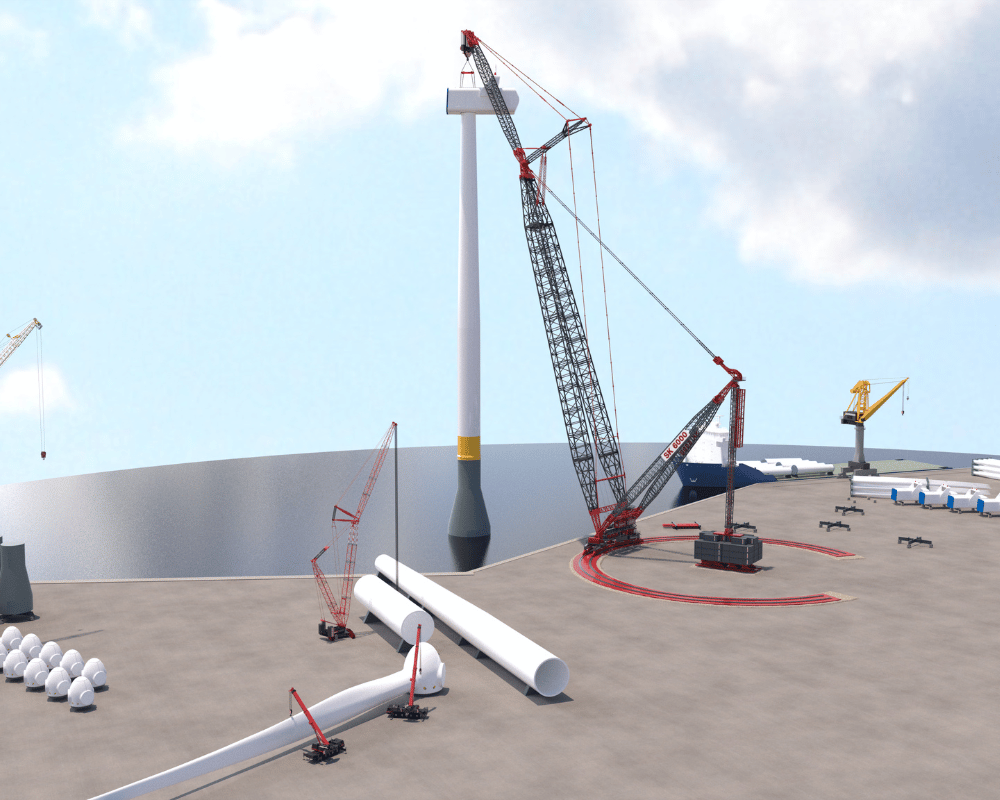

Initial components fabricated for 6,000t offshore wind giant

The first components have been fabricated for Mammoet’s SK6000 ring crane. It becomes not only the world’s largest crane, but the highest-capacity electric crane on the planet – behind Mammoet’s own 5,000t capacity SK350.

The SK6000 offers a hook height, outreach and lifting capacity far in excess of any crane on the market. As floating wind matures, its ability to launch foundations and build turbine sections without reconfiguration will maximize project efficiency.

Offshore wind components continue to grow rapidly as developers seek more reliable wind at higher heights. While larger turbines ensure maximum return on investment, this adds further pressure to a supply chain that is already struggling to keep up with the production and handling capacities required.

As a result, investment is needed on an unprecedented scale to future proof the sector and support progress towards 2030 climate targets.

With more than ten ring cranes, Mammoet is well positioned to de-risk offshore wind projects today. It is also able to invest on the scale required to support the offshore wind projects of the future.

Like the rest of the SK series, the SK6000 can be operated entirely from electric power, helping customers to reduce the carbon impact of their projects. By utilizing Mammoet’s electric SPMT power pack system, a fully electric land-based marshaling and load-out scope is now possible.

The first parts for the SK6000 have been produced at Mammoet’s fabricator in the Netherlands, and work is continuing ahead of the first phase of its assembly program later this year. Building on the established design of the SK350 series, it will support the sector as offshore wind components grow in size and travel larger distances to site.

The SK6000 is capable of lifting 3,000t components at 220m hook height, and it has a maximum radius of 144m. This allows customers to safeguard the schedules of projects, even as turbine towers, nacelles and blades expand at break-neck pace.

Its sheer lifting power also enables the SK6000 to take on lifts in the 3,000-6000t range, for example suction bucket jackets, XXL monopiles and floating wind foundations that support these quickly growing wind turbines.