Bigger turbines mean an increasing transport challenge

The growing size and weight of onshore wind turbine components means routes must be planned with precision to find the shortest options. Every extra centimeter or kilogram could rule out the ideal wind turbine transport route; any delay could have major repercussions for the previous and following phases of work.

But as wind farms become increasingly remote, developers find themselves faced with a choice: to either make costly route modifications or divert hundreds of kilometers overland - impacting later lifting and installation phases. So specialist logistics expertise is needed to bring these components to site quickly, reliably, and with lower up-front investment.

Using trendsetting technology to find the smartest routes

Advance planning is key to conquering long, complex routes to site. Avoiding long detours, obstructions and complex permitting procedures will always be the preferred option.

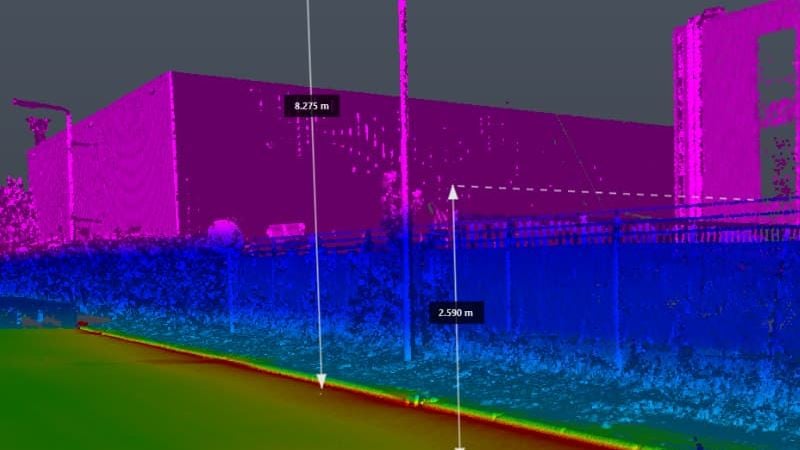

Using technologies including LIDAR and our own heavy lift and transport modeling software Move3D, we scan potential routes to identify the simplest possible path to site.

This may not always be the shortest; for example, where low bridges require temporary removal, it may be preferable to travel a longer – but less obstructed – route.

Access to the right equipment, no matter the challenge

With a range of different types of tower sections, nacelle components, blades, and other items to move, it’s crucial that transport specialists have the right equipment. Mammoet’s unrivaled inventory ensures that transportation plans can be executed in the most efficient way possible, tailored to the components you need to move.

Our expert teams are skilled in making the best use of these options. A tool kit including blade lifters, tower clamps and extendible trailers ensures that components reach site on time, and in the condition they left the factory. Our fleet of SPMT transporters can be mobilized worldwide for more complex site transports.