Expertise:

Load-in & load-out

Heavy transport

Benefits:

Optimized schedule

Flexible operations

Simplified management

Location:

Australia

Local knowledge and expertise ensures seamless project cargo delivery in Western Australia.

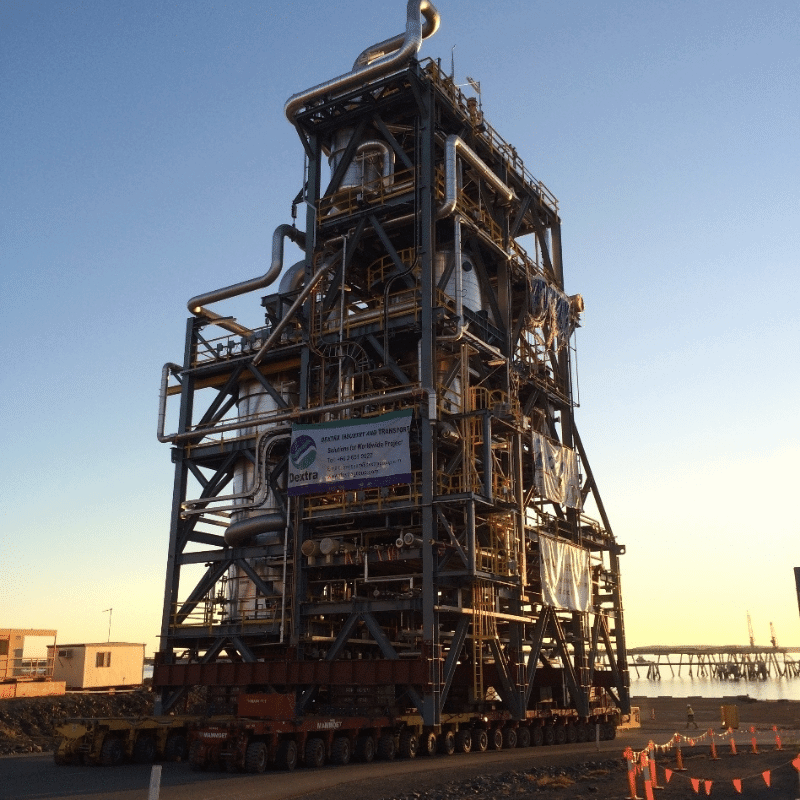

In the heart of the resource-rich Pilbara region of Western Australia, Mammoet and Dextra Transport played a pivotal role in the construction of the Yara Pilbara Nitrates technical ammonium nitrate (TAN) manufacturing plant. The project is fully modularized, with key components of the facility constructed offsite and transported to the site, increasing the cost-effectiveness of its build phase.

The project faced a daunting challenge: massive modular plant components arriving at the Port of Dampier required safe, timely delivery to the project site on the Burrup Peninsula.

This had to be achieved within a tight schedule and through a challenging transport route with up to an 8% incline. In addition, various logistical obstacles such as limited port storage, high tidal ranges, local permitting procedures, and temporary road closures posed risks to the project schedule, and so Dextra Transport teamed up with Mammoet, as an industry partner, both well reputed for their engineering skills, and with a proven track record in the region, executing projects of this nature.

With existing operational branches based in Port Hedland and Karratha, Mammoet was well equipped to provide localized support for the project. Early engagement, modular construction expertise and a strong understanding of the Main Roads WA conditions, coupled with established relationships with local stakeholders and road authorities, made Mammoet the ideal partner.

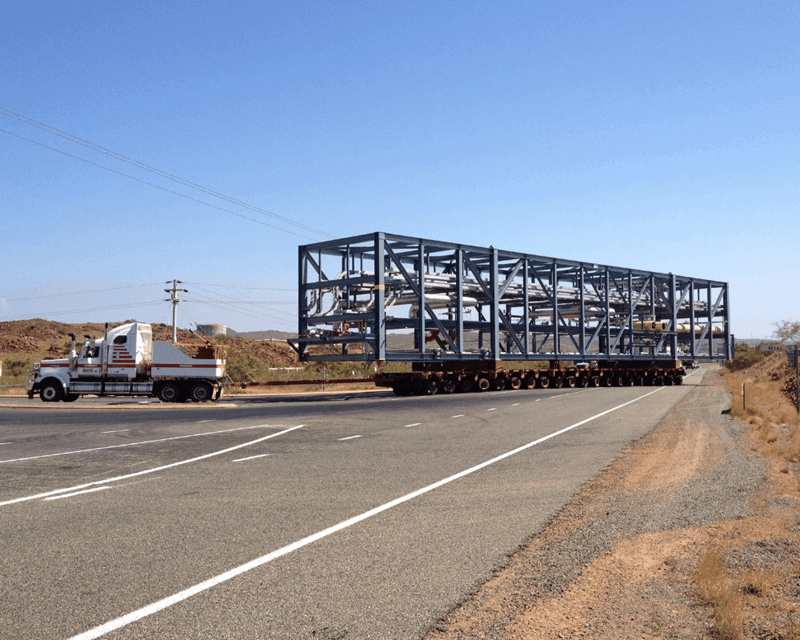

Mammoet's role was to handle the load-in and port-to-foundation transport of over 148 modules, received from ten dedicated shipments. The route had not previously been used to transport oversized loads such as these - weighing up to 900t and measuring 18 meters wide x 23.5 meters high. Facing additional challenges due to the remote delivery site and stringent governmental quarantine requirements, Mammoet navigated through these complexities.

The team performed detailed engineering studies to check the capacity and solutions for crossing underground services, including culverts and bridge checks, and identified transport route challenges early, allowing for sufficient time for upgrades and approvals.

A combination of conventional equipment and SPMTs were utilized for the project to ensure timely delivery. Notably, the use of SPMT allowed for extra-large modules to be transported as a single unit, saving significant time in construction and integration.

The approval process was further complicated by traveling on the route at night. This required a detailed route study, road modifications, bridging and propping culverts, and the implementation of a rolling roadblock under traffic management - a first on this route.

Lee Chapman, Business Development Manager Mammoet Australia, commented:

"The project team’s commitment to overcoming challenges and delivering the plant’s components was truly remarkable. Early engagement in the project played a crucial role to achieve timely delivery of project components. They were delivered on time, at the right time, within tight deadlines and challenging conditions, showcasing our commitment to our clients' success."

Developed through a joint venture between Orica Limited and Yara International ASA, the Yara Pilbara TAN manufacturing plant boasts a capacity to produce 330,000 tonnes of ammonium nitrate annually. This critical component of explosives is pivotal in the mining, quarrying, and construction industries, driving economic growth in the region. It is also the world’s first modular ammonium nitrate plant.