Sector:

Nuclear Power

Expertise:

Gantry lifting

Heavy transport

Skidding

Benefits:

Increased safety

Parallel operations

Protected infrastructure

Location:

United Kingdom

Custom-engineered solution developed over years negotiated curved route into reactor building.

With different contractors working on the same site operating a wealth of machinery and equipment, effective planning and communication are critical to ensure a successful nuclear construction project. Operations must be meticulously planned and performed safely to ensure that the site delivers to program.

What’s more, years of engineering are needed to develop a solution that can deliver high-value loads for installation around pre-existing structures. Design choices mean that space on site is at a premium and a smartly engineered solution is required.

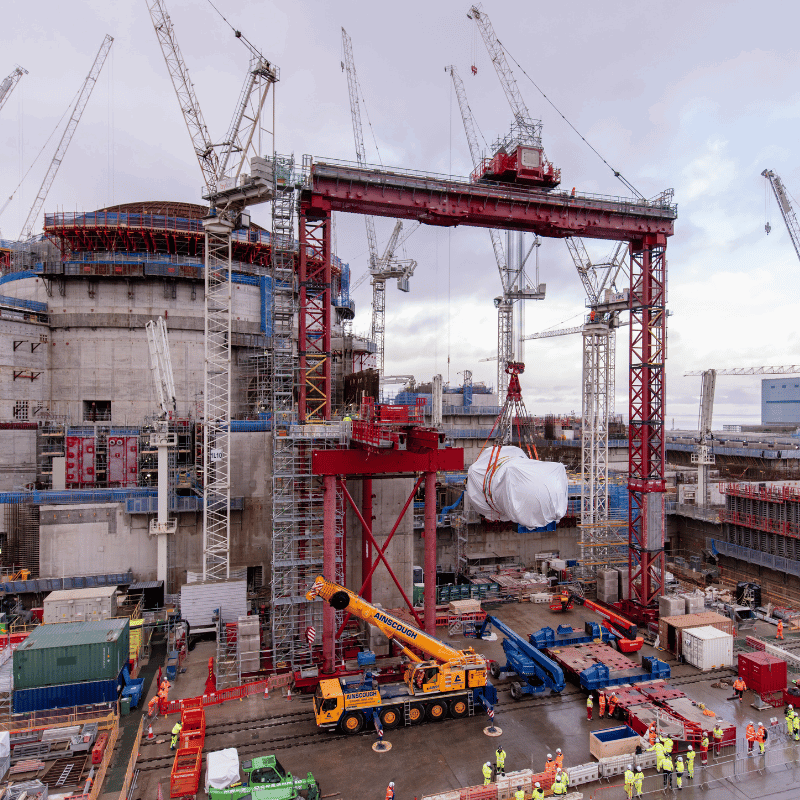

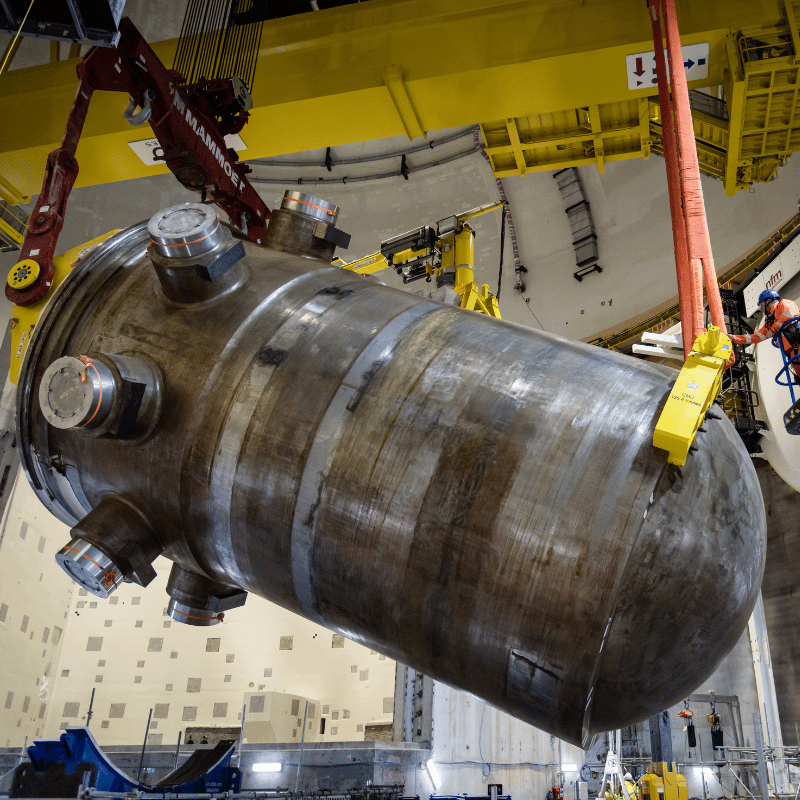

In Somerset, UK, the first of a generation of planned nuclear sites was under construction by EDF and its contract partners. Framatome, the manufacturer of its reactor pressure vessel and steam generators, approached Mammoet to handle their most sensitive components.

These components - weighing up to 520t - are the beating heart of the nuclear plant and will provide power to three million homes per unit.

Framatome required a technical solution that was not reliant on any pre-existing on-site lifting equipment. This was to ensure that the operation could be performed safely and to schedule, around other work.

Mammoet has considerable experience of custom engineering to support the construction, maintenance and decommissioning of nuclear power plants globally – and so its experts set to work.

On track to install the components

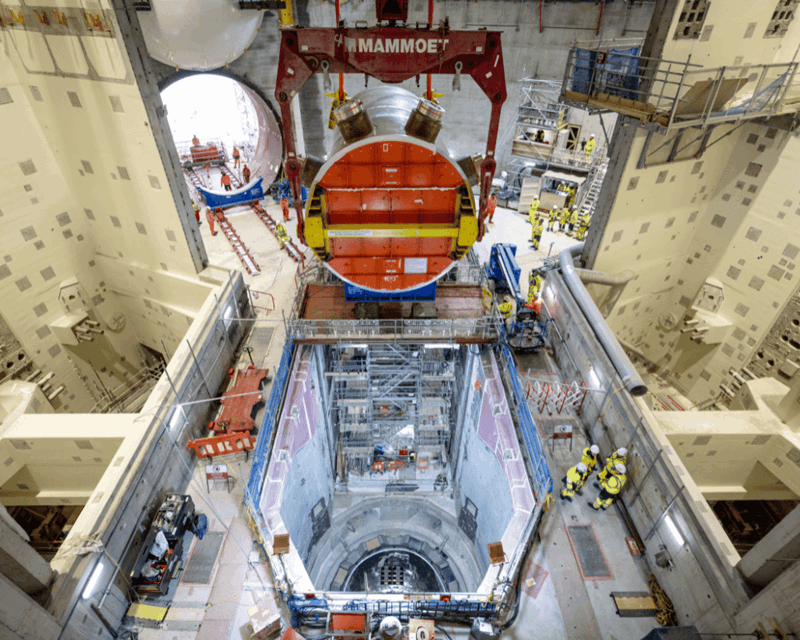

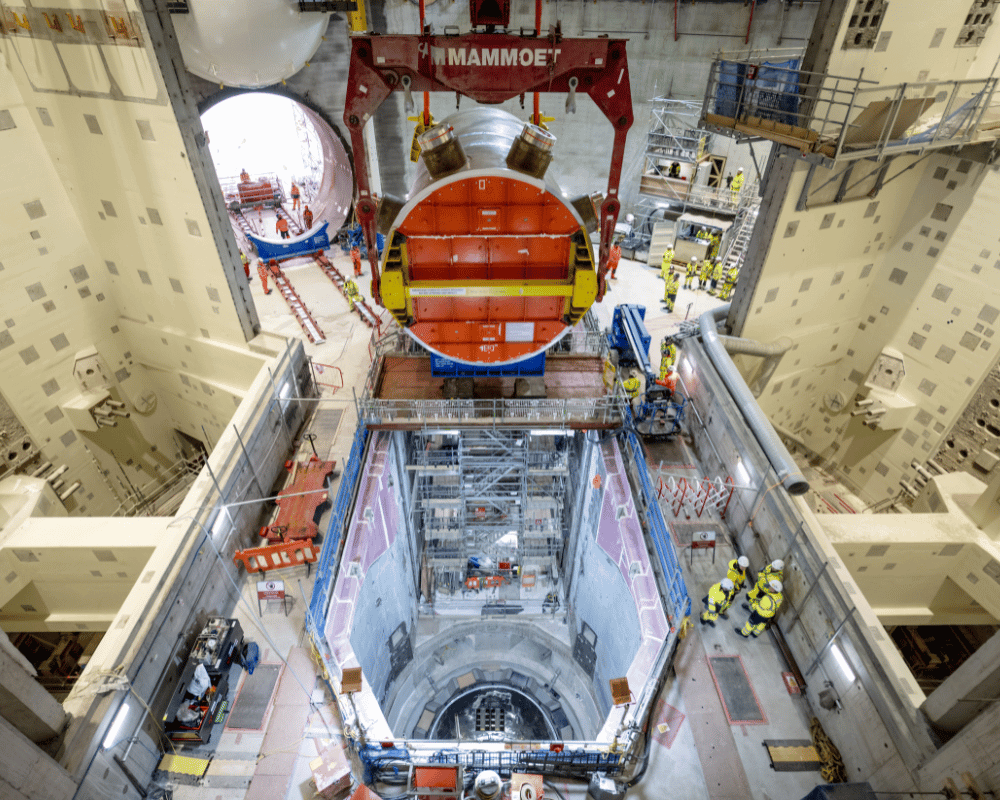

The biggest technical challenge for Mammoet’s team was how to deliver all components through a small opening in the reactor building.

“The congestion around the unit, and the spatial limitations within which we were required to perform our activities gave Mammoet an interesting challenge” explains Darren Watson, Sales Director at Mammoet.

“We engineered a solution, including a gantry system, which spanned from the identified pickup location and would bring the components to the required height for relocation into the building. This system also had to lift and maneuver these large sensitive components”.

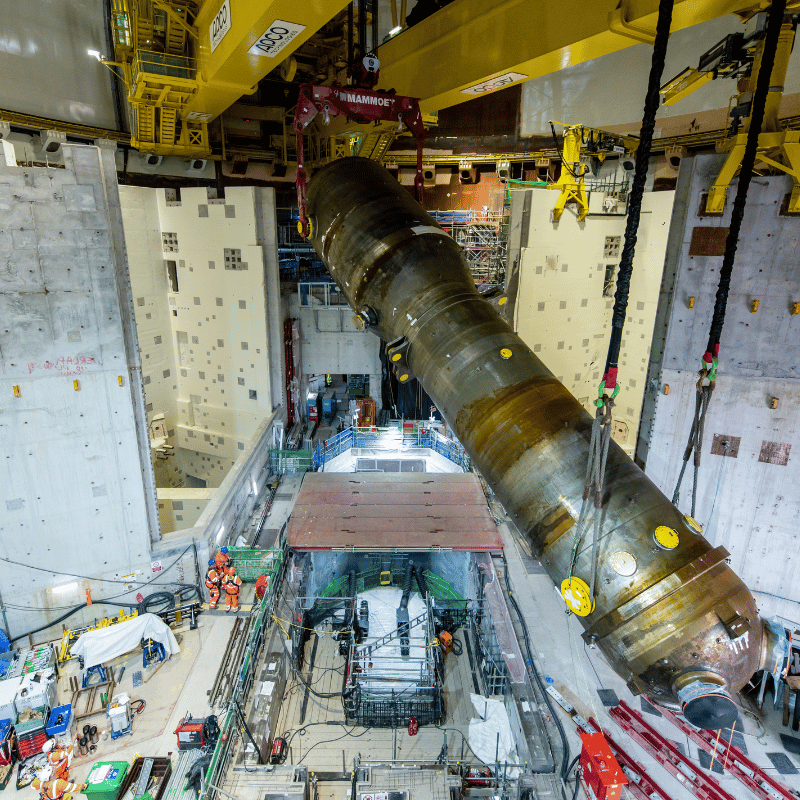

To achieve this, Mammoet’s engineers designed and constructed the OLS (Outside Lifting System). Using a combination of winches and strand jacks, the OLS lifted the components directly from SPMT and, as part of a controlled operation, lowered them onto a skid system enabling their transition into the building.

Typically, skidding systems are laid in straight lines. However, due to the shape of the reactor building, a 30-degree curve was needed. This would allow the components to enter the structure at the correct angle for subsequent installation.

This system incorporated a turntable - tailor made to accommodate the transport saddles for the components - which allowed the units to be rotated as they traveled along the skid path.

Once transitioned inside of the building, the components were lifted and rotated from horizontal to vertical orientation before being lowered into their final installation position. For this operation, two Mammoet Temporary Lifting Devices (TLDs) were fitted to the existing polar crane.

The larger TLD, with a capacity of 600t, performed the main lifting operation using a containerized winch for the hoist. The second TLD, with a 320t capacity, used strand jacks to complete the reorientation of the loads.

The equipment, teams and experience to deliver

This grid powered solution also helped to reduce the carbon impact of the project, with a reduced level of noise, leading to a safer working environment.

“The ability of our engineers to develop bespoke solutions to perform these highly complex operations is one of many areas where we add value to nuclear power projects,” adds Watson.

“Our experienced teams, extensive toolbox, and track record for operational excellence and safety is what sets Mammoet apart. Few companies can even dream of delivering the types of projects Mammoet can perform”.

Mammoet has considerable experience of using specialist lifting and transport equipment for nuclear projects, previously deploying a gantry system for component installation at Flamanville, France, while Mammoet’s PTC35 crane is helping to extend the Bruce Power facility in Ontario, Canada.