Sector:

Offshore

Expertise:

Load-in & load-out

Jacking

Skidding

Benefits:

Parallel operations

Optimized schedule

Increased safety

Location:

Vietnam

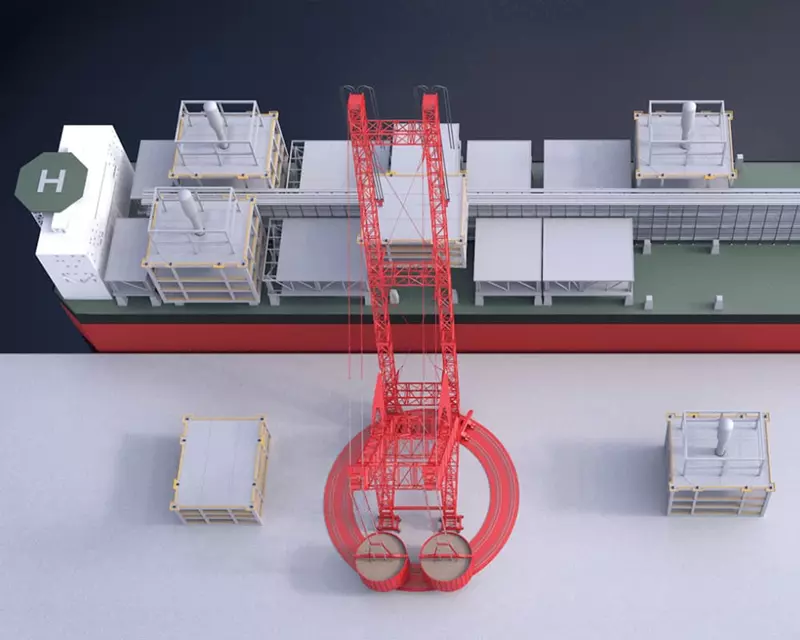

In a yard in Vung Tau, Vietnam, a large Processing and Quarter Platform (PQP) and its load-out support frame were built simultaneously which saved a significant amount of production time and allowed the offshore installation date of the module to take place earlier.

After construction of both the PQP and the frame was complete, Mammoet was faced with the challenge of lifting the 12,000-tonne platform, installing it on top of the frame and loading the combined structure out onto a barge. Mammoet offered the customer a comprehensive solutions package: jacking, weighing, skidding, ballasting and mooring. Mammoet had previously assisted in the assembly and load-out of the 11,500-tonne jacket which would support the platform at sea.

Mammoet began by jacking the platform up to 13 meters and weighing it. Mammoet then lowered the deck onto the frame. For the load-out, Mammoet skidded the combined structure, which now weighed over 14,000 tonnes, across 175 meters to the quayside. Finally, Mammoet skidded the structure slowly onto the barge while ballasting the barge. This procedure kept the barge level and offset the changing tide to ensure the safe delivery of the platform.

The asymmetrical weight distribution across the structure posed another challenge. This phenomenon required that the barge had to be ballasted asymmetrically. An additional counterweight was placed on the platform to partially compensate for the asymmetrical weight. Mammoet’s computerized ballasting system with 38 pumps made this procedure possible.