Sector:

Civil Engineering

Expertise:

Gantry lifting

Skidding

Benefits:

Increased safety

Optimized schedule

Location:

United Kingdom

The largest sections could be extracted faster and dismantled at ground level

When it comes to dismantling large underground machinery, it is far easier – and safer – to carry out this work above ground. Performing it in confined areas – with cutting equipment generating fumes and heat – can put operators at risk.

In order to excavate larger tunnels, Tunnel Boring Machines (TBMs) have grown to be colossal in size and so getting them out of the ground can be a significant challenge, particularly in urban, built-up areas.

This was the challenge facing Mammoet in removing TBMs manufactured by Herrenknecht and used to excavate tunnels for High Speed 2 (HS2) – the high-profile British rail project linking Birmingham and London.

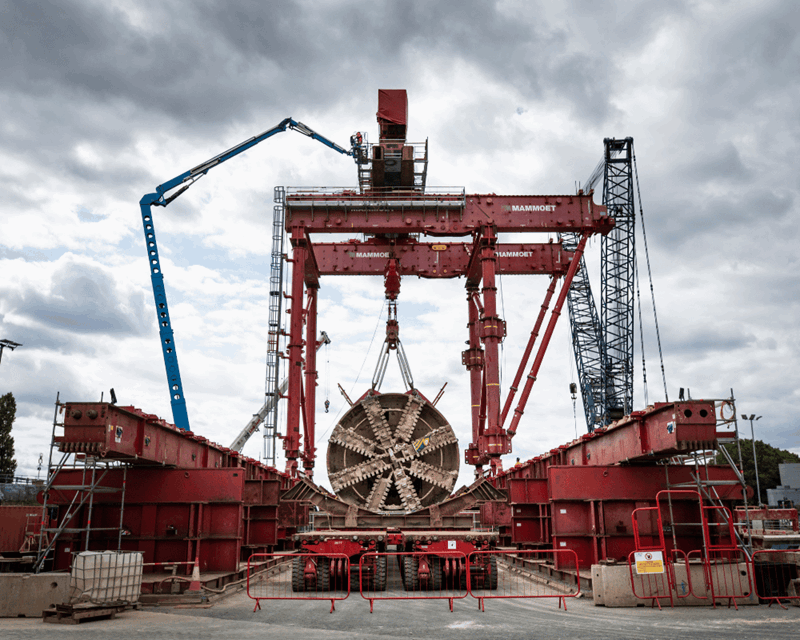

The objective was to remove four TBMs on the outskirts of London. Through close collaboration with Skanska Costain STRABAG JV and Herrenknecht, a gantry solution was custom designed and assembled - which provided significant benefits.

This solution enabled the removal of the TBM as a single piece - saving time - and reduced dismantling operations within the shaft by bringing lift operations to the surface - mitigating risk.

The TBM sections were able to be removed from the tunnel in a single day instead of weeks.

Rise of the machines

Four TBMs were used to excavate the 8.4-mile Northolt Tunnel section of the HS2 route. The tunnel consists of two (twin) tunnels. In each tunnel, two TBMs were launched from the opposite ends of the route, digging towards each other until they met at a central point – Green Park Way vent shaft site - which has two shafts.

The ventilation shafts are 35 meters above the tunnels, and the location where all the TBMs were extracted from once they have completed tunnelling. Mammoet’s intention was to remove the biggest components – the cutter head, front and middle shield – in a single lift so that they did not need to be taken apart.

The challenge was lifting them out – particularly on a site just a few meters away from two live railway lines, in a busy city, and with other civil works taking place nearby.

“Different approaches were considered at the start”, explains Darren Watson, Sales Director at Mammoet.

“One option was that the TBMs would be split and disassembled within the shaft and the component parts lifted out by a crane. However, this would have meant people working down there in a very congested space, with ventilation issues to overcome and a large crane taking up a significant portion of the compound area above, interfering with other works on site”.

Collaborating closely with SCS JV and Herrenknecht, Mammoet proposed a different solution – a bespoke gantry system to extract the front and middle sections in a single lift and place them onto SPMTs, transporting them to a disassembly area on site.

Design of the custom-built gantry system began around nine months prior to execution. Once approved, it went into a detailed engineering phase of five months. The gantry was then constructed on site over the period of one month.

Creating the gantry system

While much of the equipment used to construct the gantry system already existed, it had never been assembled into this arrangement. There was also an element of fabrication required to realise its design and give it the ability to lift a maximum weight of 900t.

The gantry was mounted onto a hydraulic skidding system, which allowed it to move backwards and forwards so that it could be positioned over the openings of the two vent shafts. It was also designed with an equalizer beam containing an inbuilt swivel to bring everything to a central point. This enabled all components which were lifted to be rotated.

“Normally, if that was any other piece of equipment, you would have to attach another system and exert external force onto the load to turn it. This would require a lot of manual handling.

We created a system that could be remote controlled for ease of operation,” explains Sam Ellwood, Lead Engineer at Mammoet.

“This avoided us having to use taglines and winches – and besides, we would have had to get close to the load to attach items to it. Our solution allowed us to be ‘hands off’, so that everything could be kept isolated. This made for a safer operation”.

This manoeuvrability was of particular importance as the design of one of the vent shafts differed from the other. Beneath the ground, it undercut the nearby railway track.

Moreover, while the underground HS2 line runs parallel with this train line, the skidding track could not. Therefore, a slight turning operation was required, mid-lift, to put the TBM section in the right orientation for skidding.

Once each TBM section was successfully lifted out of the vent shafts, the gantry was moved and positioned over 32 axle lines of Self-Propelled Modular Transporter (SPMT), parked between the tracks of the skidding system.

Holding a steel cradle to support the sections during transit, the SPMTs then drove them to an area on site for disassembly, lowering them to ground level for further dismantling using climbing jacks. This reduced the need to work at height when removing the hydraulic rams, drive motors and other ancillary equipment inside.

The extraction program was a hugely complex exercise in collaboration and teamwork between Mammoet, Herrenknecht, SCS JV and the wider HS2 team. Herrenknecht International Ltd Managing Director Richard Dexter:

“The two – and, more widely, four - site teams had to erect and commission the system at the start of the year, and then, several months later, coordinate lifting in twelve-hour windows during weekend railway possessions.

The total works needed four 24-hour lift and carry operations. These were, in turn, based upon four week-long preparations, two month-long assemble and disassemble periods and eight months of intense engineering, design, planning, structural analysis, materials and weld testing - as well as possessions and community engagement”.

A solution for future TBM extractions

This project demonstrates how Mammoet helps its customers to reduce time and costs on projects through consideration of the entire project scope, allowing for delivery of a highly detailed engineering solution.

“Herrenknecht and Mammoet were aligned in our goals and worked closely together” adds Watson.

“As a team we wanted to remove the load in the largest piece possible, removing the need for size reduction, and extracting the TBM in as little time as possible.

It is a very collaborative working relationship; ‘’Herrenknecht see the value we can bring to the table when it comes to complex lifts”.

Dexter agrees:

“It has been one of the smoothest real-time demonstrations of relationships developed over many years, brought into play to solve a considerable challenge.

Together, all of the teams yielded large time savings for the project, in the form of early access for follow-on tasks of several months in each of the four tunnels”.

Mammoet is already looking ahead to other projects that could utilize the gantry system. It could be used for a wide variety of applications that require heavy lifting in confined spaces.