Sector:

Offshore

Expertise:

Load-in & load-out

Skidding

Benefits:

Protected infrastructure

Increased safety

Location:

United Kingdom

The Brent Field, lying 186km northeast of the Shetland Islands, is one of the largest fields in the North Sea and has three gravity base structures, Bravo, Charlie, and Delta, and one steel jacket – Alpha.

It is a 50/50 joint venture between Shell, as operator, and Esso. Decommissioning Brent is a complex, major engineering project, because of its size, age, infrastructure, and the harsh environment of the North Sea.

Brent Delta ceased production in 2011, Alpha and Bravo in 2014, and Charlie is still in production. The Delta topside was removed in a single lift in 2017 by Allseas’ vessel Pioneering Spirit, and taken to Able UK’s facility in Hartlepool, North East England, where over 97% has been recycled. Brent Bravo’s 25,000t topside was lifted in June 2019, by the Pioneering Spirit.

Mammoet’s scope was to perform the load-in of the entire Brent Bravo topside at Able UK. Due to the complexity of the project, the project demanded careful planning, collaboration, significant flexibility and strict time management within narrow windows of opportunity.

The operation began a week prior to the topside arriving onshore, as the Pioneering Spirit positioned itself around the platform and lifted it in an operation that took four hours. From its initial position on top of the concrete legs 140m deep, the Brent Bravo topside was lifted in one piece and secured by the lifting system of the vessel.

After removal from its concrete leg structure and transport to the northeast coast of England, Brent Bravo was transferred onto the Iron Lady, a purpose-built 57m x 200m barge. The barge was towed for the remainder of the journey, mooring at Able Seaton Port near Hartlepool.

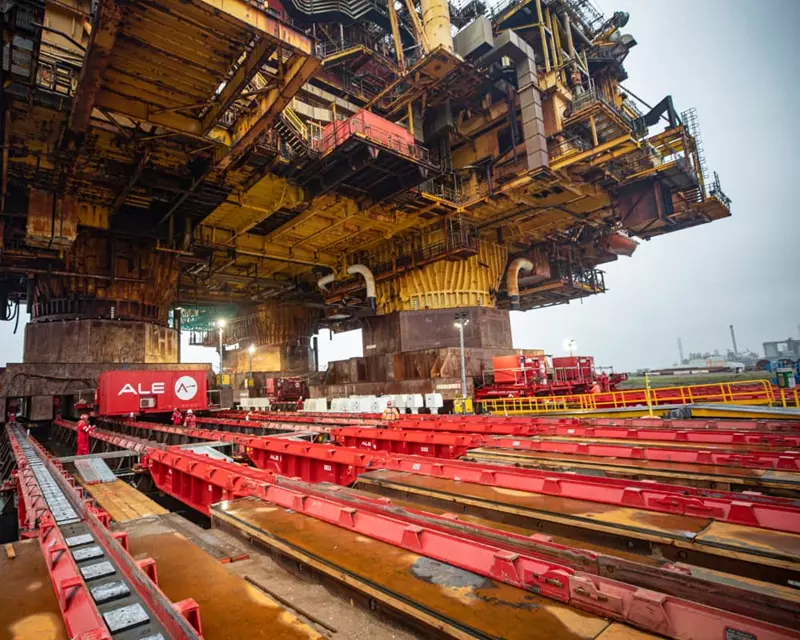

The barge was then maneuvered in front of the quayside, ready for load-in preparations. Here, Mammoet installed skidding equipment on the demolition pad at the port, plus several hinged link beams, extending the skid tracks from the barge to the quay in order to guarantee safe and stable load-in.

The topside was then taken over onto the skidding system by means of the internal hydraulic cylinders of the skid shoes. This system consisted of 12 500t skid shoes, 48 650t skid shoes, 12 800t skid shoes, 32 push-pull units, and three hydraulic power units; all overseen by state-of-the-art control systems to coordinate and monitor the movement.

In total, the topside was skidded 105m over the course of six hours. Brent Bravo was then handed back to the client for dismantling and recycling.