Sector:

Case study

Nuclear Power

Expertise:

Heavy lifting

Heavy transport

Benefits:

Optimized schedule

Increased safety

Location:

Germany

Removing the steam generators intact ensured a safer, more efficient extraction

Winner of the BSK Award 2025 in the Installation category, 1st place

When removing steam generators from decommissioned nuclear reactor buildings, the most economical method is to remove them in one piece.

Cutting involves the risk of contamination spreading in the control area and must therefore be carried out in a safe and controlled environment – which often requires the construction of expensive protective structures on site.

Rip and ship – a term widely used in the nuclear sector – refers to a method of removing them intact so that they can be taken immediately off-site to specialist nuclear waste disposal facilities.

The challenge with older nuclear power plants is often a lack of usable space. Many were designed without decommissioning in mind, which means removing equipment is often difficult.

Mammoet was commissioned by Framatome to support with the removal of four steam generators from PreussenElektra’s Nuclear Power Plant Unterweser in Germany.

The team of nuclear experts and engineers from Framatome and Mammoet, jointly developed a process that enabled the steam generators to be removed from the reactor building in one piece, thereby helping to optimize the decommissioning process.

An expert team with special handling equipment

Mammoet’s involvement began four years prior to the project, when PreussenElektra invited it to be as a specialist advisor on possible extraction methods for the steam generators.

After investigating various strategies, PreussenElektra opted for the most economical solution: removing the steam generators in one piece. Mammoet delivered a reliable and safe concept for this.

“Owners and operators always consider all planning dimensions for the decommissioning process”, explains Andreas Franzke, Senior Sales Manager & Segment Lead Power & Nuclear at Mammoet in Germany. “Process optimizations lead to cost savings, because every day of dismantling results in costs. One way to optimize the process is to remove the steam generators as a whole.”

Working with Framatome, Mammoet came back with an engineering solution to remove the 300t steam generators from the reactor building without dismantling them.

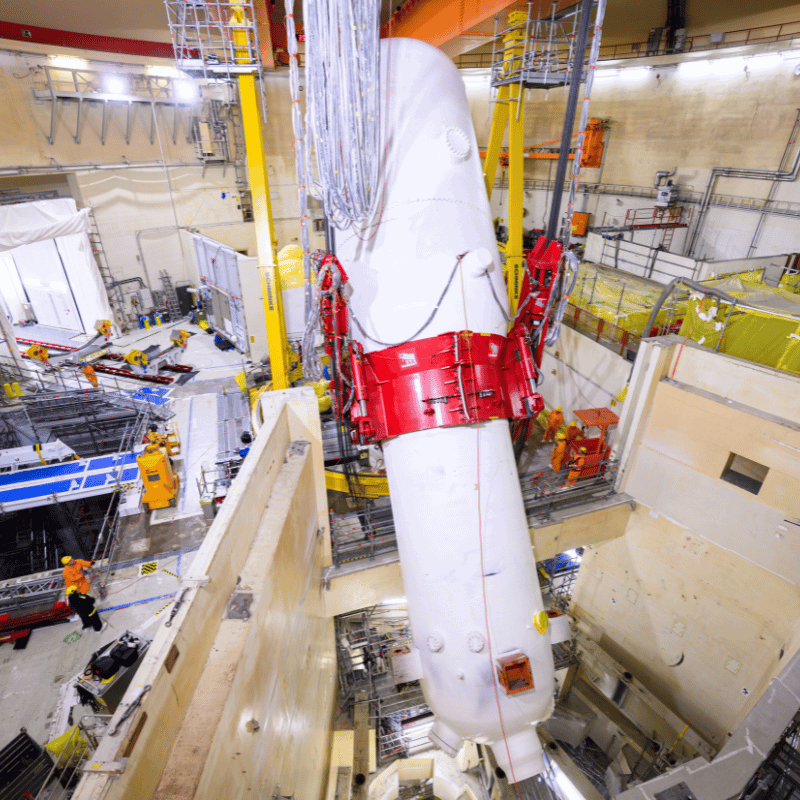

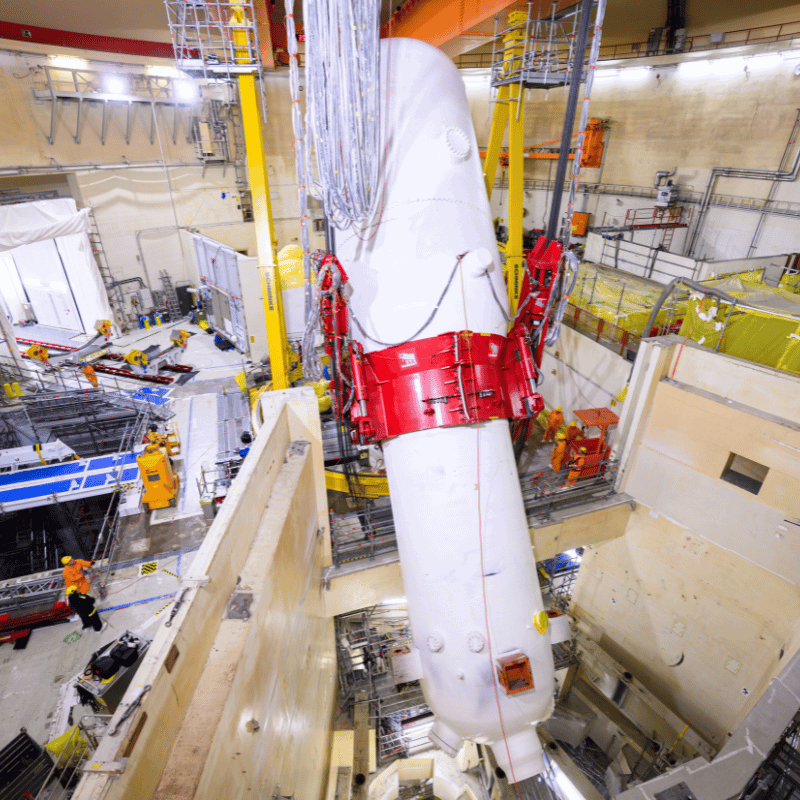

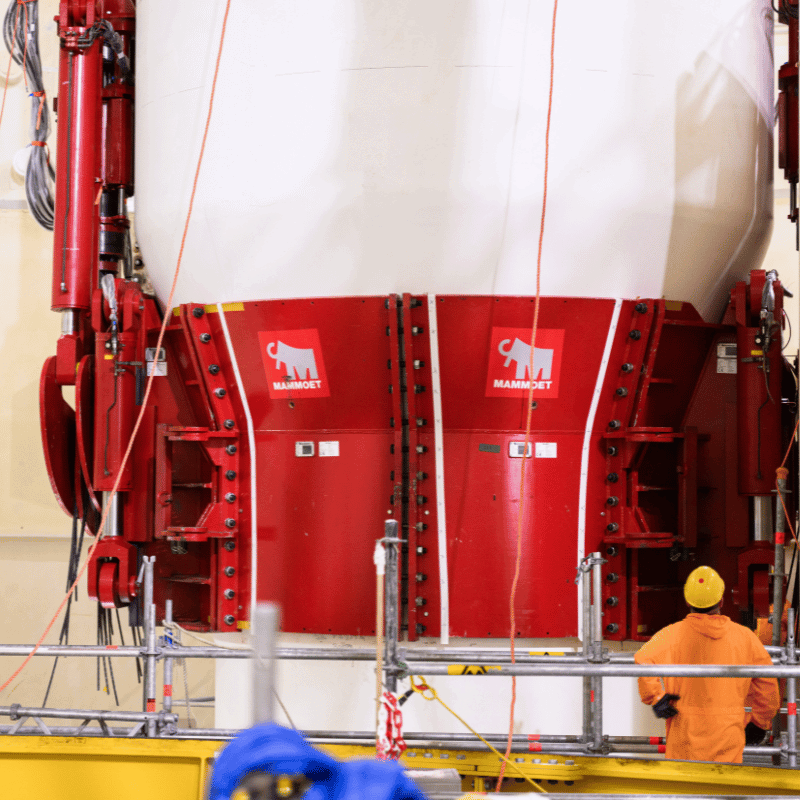

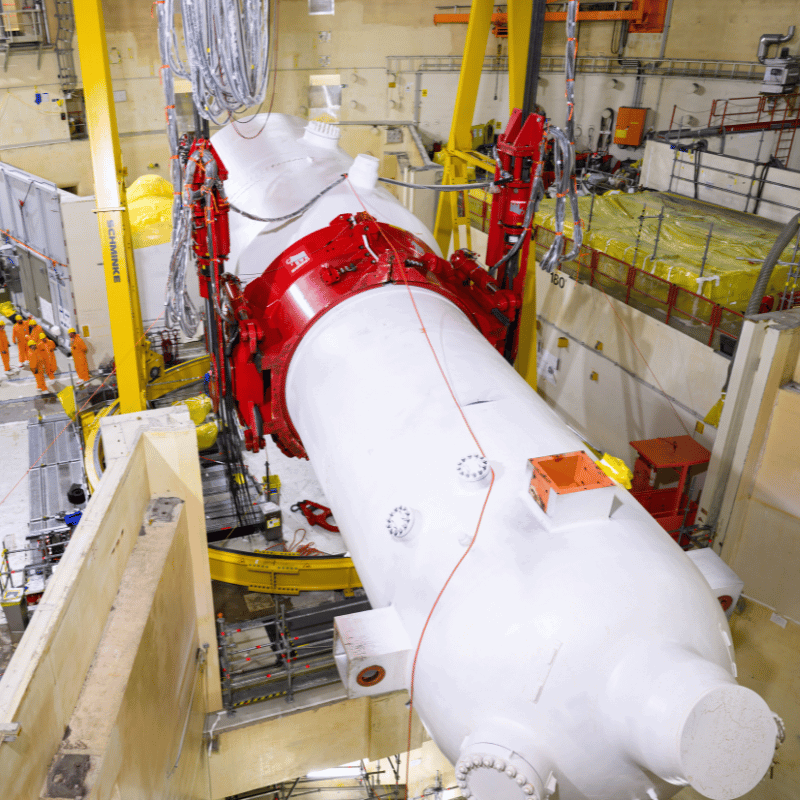

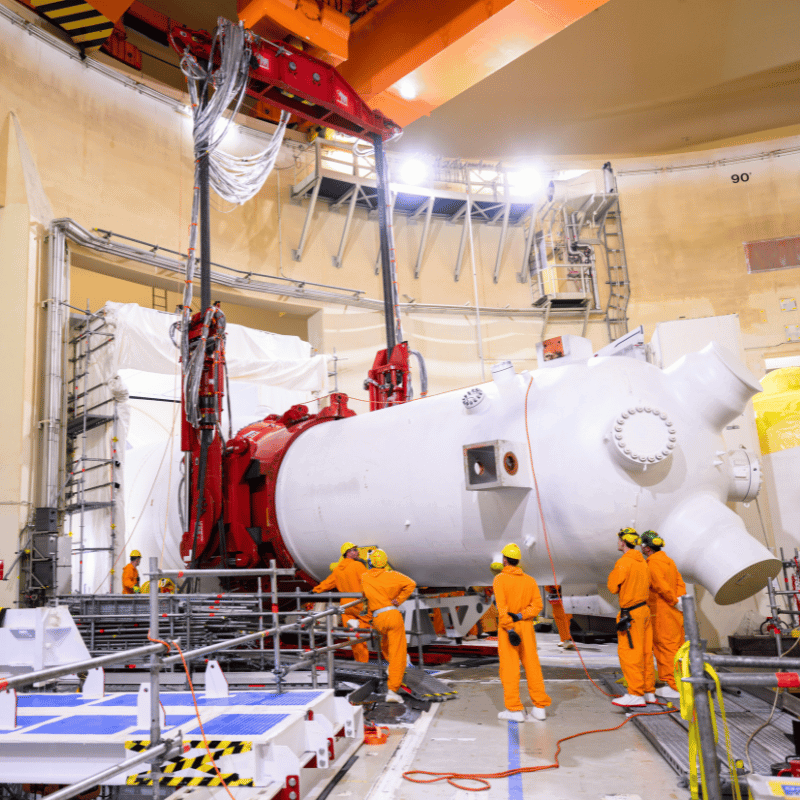

Mammoet would lift them using its self-developed DHS-500 system. This special tool can manoeuvre the steam generator in any direction and around all obstacles inside the confined reactor building.

The DHS-500, which can be customized to the conditions of a building, comprises a top spreader beam that can be bolt-fastened to the hook of overhead cranes. Using an adjustable ring designed to grip the cylindrical steam generators.

Another benefit of the system is that the tilting and pivot point can be adjusted to the centre of gravity by using a hydraulic cylinder, providing the tilting operation with much greater stability and safety.

“It is the most efficient way to perform this job”, explains Tom Schladitz, Project Manager at Mammoet. “Our equipment is not only designed to make complex operations like this easier, but it is also approved by the appropriate German authorities, giving our customers further confidence.”

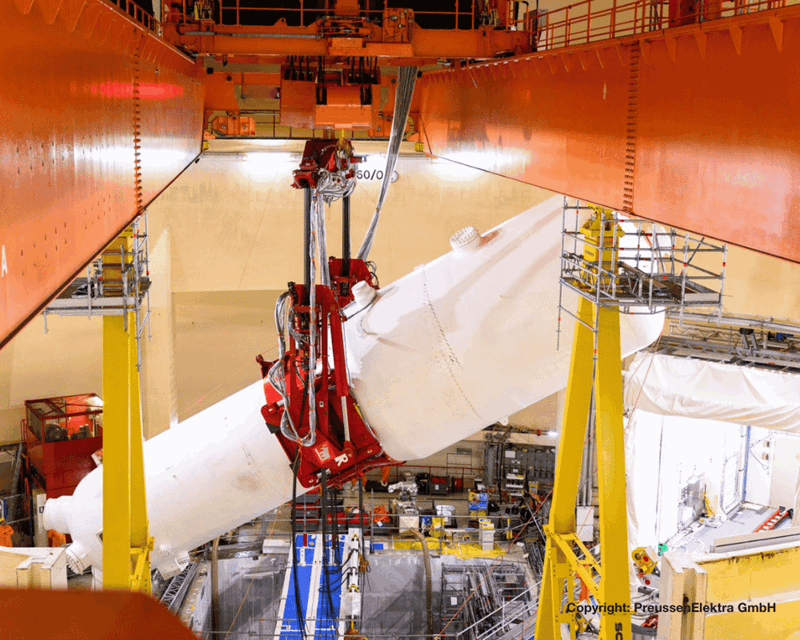

The DHS-500 allowed each steam generator to be lifted, tilted from a vertical to horizontal position, and easily manoeuvred around obstacles blocking its route to the exit.

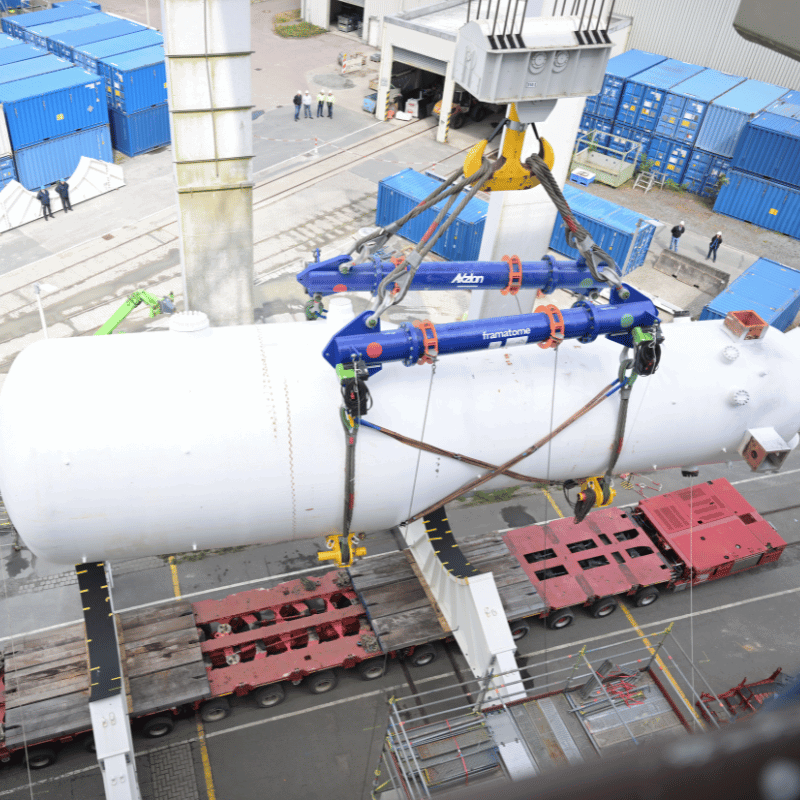

A skidding system was used to move the steam generators through the elevated lock of the reactor building. They were skidded to a position just outside and then rigged to an overhead portal crane.

The portal crane then lowered the steam generators 25 meters onto 16 axle lines of Power Steering Trailers.

The trailers were fitted with transport and storage saddles, to secure the steam generators safely during transit and when stored in a laydown area on-site.

Experts in rip and ship for the nuclear sector

Mammoet has a lot of experience of rip-and-ship steam generator removals and was able to bring that working knowledge to this job. It provided the required technology, experienced team and execution concept to ensure that everything was performed as planned.

Its nuclear team is global, with experts from Germany, the Netherlands and other parts of Europe working together to execute high-profile nuclear projects all over the world.

Mammoet will often work with clients, owners and operators over an extended period of collaboration, assessing different concepts and solutions to ensure that each operation is safe, efficient and completed in the shortest time possible.

Removing the steam generators in one piece enabled the client to optimize the decommissioning process, freeing up space faster to allow other dismantling work to take place.