Sector:

Mining & Metals

Expertise:

Heavy transport

Load-in & load-out

Benefits:

Optimized schedule

Record breaker

Parallel operations

Location:

United States

Rewriting the rules for modular construction.

In the remote Delong Mountains of Alaska lies one of the world’s largest sources of zinc – the Red Dog Mine. The weather window for building the processing plant was extremely small: only three months.

As it was impossible to build the entire plant on location in such a limited time frame, Mammoet was asked to help conceive an alternative solution. Long before the first ore was processed, Mammoet began orchestrating a plan to build, transport, and install the plant in large-sized modules.

After a short construction window, winter would make it impossible to build on or even get to a site in the Arctic Circle. This meant the Red Dog plant somehow had to be built within a 100-day timeframe. This included time needed for transporting materials over the Arctic waters and through the harsh and desolate mountains.

To solve this seemingly impossible problem, Mammoet was brought onboard in 1986, three years before construction of the installation had even begun.

The only way to get the job done in the available timeframe was to build and deliver the plant in large modules. Modular construction on this scale had never been done before. The sheer size of the modules alone made this project a game-changer in the industry.

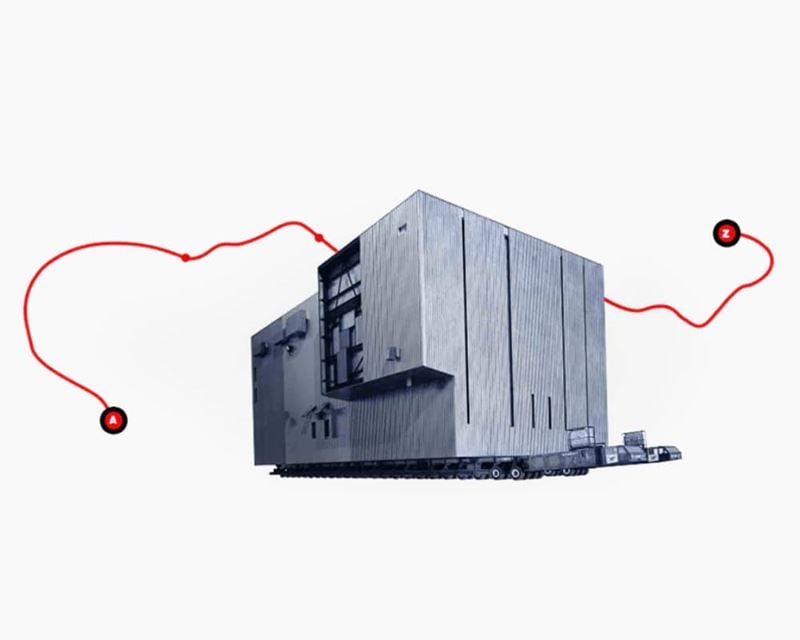

A total of 18 modules up to 1,800 tons each were built in the Philippines and then shipped to Alaska. Based on a pre-construction analysis, they were designed in such a way as to optimize them for transport and construction. To move the installation over land, Mammoet used its newly developed Self-Propelled Modular Transporters. The SPMTs high payload capacity and great maneuverability reduced the road width requirements between port and site. A revolutionary trailer system at the time, SPMTs are now widely used in the industry.

By building the installation in the favorable climate of the Philippines, time was no longer a restricting factor during construction. It also meant that fewer people were exposed to the treacherous Alaskan weather conditions.

In an operation that involved creative planning, revolutionary engineering, and exceptional teamwork, Mammoet rewrote the rules for modular construction. By the time the first snow started to fall, the Red Dog mine was already up and running.