Sector:

Nuclear Power

Expertise:

Heavy lifting

Crane lifting

Benefits:

Reduced disruption

Increased safety

Protected infrastructure

Location:

Belgium

Sometimes the toughest route is the fastest.

In 2004, two steam generators at the Doel Nuclear Power Station needed to be replaced. Mammoet was asked for a solution that would keep plant outages to a minimum.

The conventional solution of skidding the steam generators through the side of the reactor building would take too much time. Instead, Mammoet proposed to exchange them through the roof. A safe alternative approach that got the job done faster than the conventional way.

In the 1990s Mammoet replaced the steam generators for Doel 3 and 4. Back then, we used the conventional method of skidding the steam generators through the side of the building. The downside of this procedure is a large amount of time lost while removing components to create space inside the reactor building to move the steam generators in and out. With this in mind, the Mammoet engineers started working on alternatives.

Fortunately, a lot had changed since then. Because of technological advancements, our crane fleet had reached record heights of lifting capacity. Instead of having to go in from the side, we could now come in from above. As a result, there was no more need to disassemble components inside the plant other than the steam generators themselves. We had already won time before we had even begun.

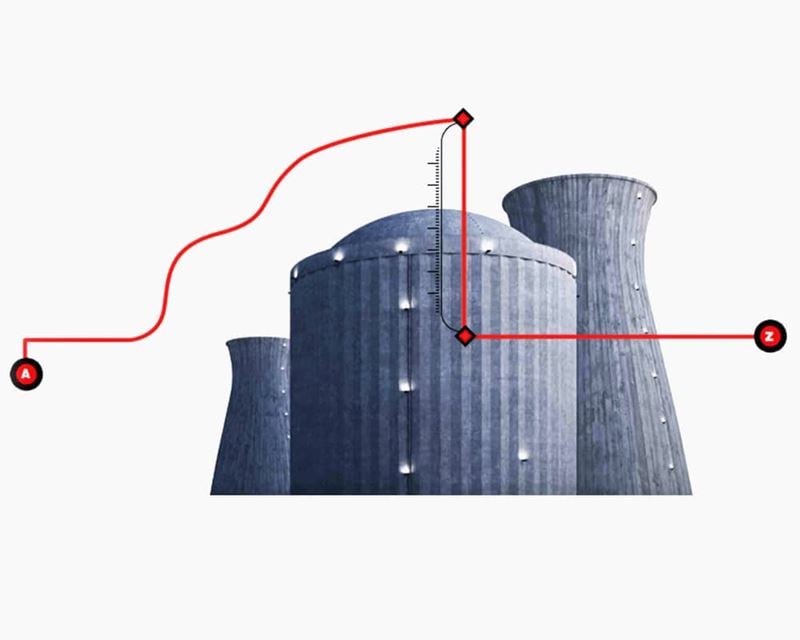

Before the old steam generators could be replaced with new ones, a number of panels had to first be removed from the roof of the reactor building. The old steam generators were then extracted with a 1,600-ton PTC35 ringer crane and tailed in a horizontal position with a 500-ton hydraulic crane.

Once the old steam generators were placed on stools in the storage building, we transported the new units from the temporary storage area and lifted the two new 313-ton steam generators into place through the openings in the dome. Fast, safe, and efficient.

Through this innovative approach, outage time was reduced by 10 days (30%). As a result, the region never came anywhere close to losing power. Less time in and around the plant also meant less exposure time for the crew involved, no insignificant fact in a field where safety comes before everything else.

Five years later, this same client asked us to replace the steam generators for Doel 1 following the same procedure. The entire plant was now up to date again for years to come.